Cone Crusher Wear Parts: Enhancing Performance and Durability

Introduction

Cone crushers are vital equipment in mining, aggregate production, and recycling industries. They are designed to crush hard and abrasive materials into smaller, more manageable sizes. At the heart of a cone crusher’s functionality lie its wear parts — components that take the brunt of the crushing process. Cone crusher wear parts directly influence efficiency, longevity, and overall plant performance.

This article explores the key types of cone crusher wear parts, the materials used in their construction, factors affecting their lifespan, and best practices for maintenance and replacement.

What Are Cone Crusher Wear Parts?

Cone crusher wear parts are replaceable components that come into direct contact with the material being crushed. As the crushing chamber wears down from constant use, these parts must be replaced to maintain consistent output and efficiency.

Key Cone Crusher Wear Parts

1. Mantle

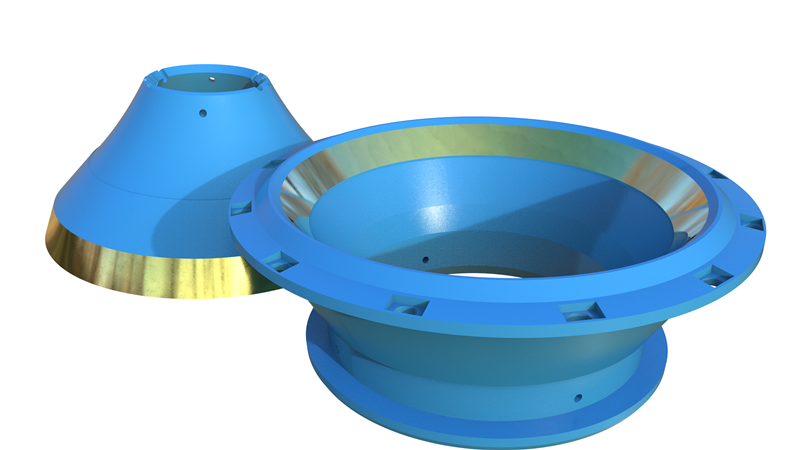

The mantle is the moving wear part that gyrates within the crushing chamber. It is mounted on the main shaft and performs the actual crushing by pressing the material against the concave. The mantle endures constant stress and high-impact forces.

2. Concave (Bowl Liner)

The concave, or bowl liner, is the stationary part of the crusher. It lines the inside of the top of the crusher bowl and acts as the counter surface to the mantle. When material enters the chamber, it gets compressed between the mantle and the concave, where it breaks into smaller pieces.

3. Feed Cone (Distributor Plate)

Located at the top of the cone crusher, the feed cone ensures even distribution of material into the crushing chamber. It reduces wear on the mantle and concave by distributing the load more uniformly.

4. Torch Rings

These are rings used to secure the mantle in place. Though small, they are critical for holding the wear parts together under extreme pressure and vibrations.

Materials Used in Cone Crusher Wear Parts

Choosing the right material is essential for optimal wear life and crusher performance. Common materials include:

Manganese Steel

This is the most common material used for cone crusher liners. It comes in various grades like Mn13, Mn18, and Mn22. Manganese steel is known for its high impact resistance and work-hardening properties — it becomes harder as it’s subjected to pressure.

Chromium Steel

High chromium alloys are sometimes used in specific applications where more resistance to abrasive materials is needed, though they are less impact-resistant than manganese.

Titanium Carbide (TIC) Inserts

For highly abrasive and hard materials, cone liners with embedded TIC inserts offer extended wear life by combining the toughness of manganese steel with the hardness of carbide.

Ceramic Composites

Advanced ceramic-metal hybrids offer improved wear resistance, especially in high-speed or extreme-duty crushing operations.

Factors That Affect Wear Part Performance

1. Feed Material Properties

The hardness, abrasiveness, and moisture content of the material being crushed significantly impact wear rates. Extremely hard or non-uniform material causes faster degradation.

2. Crusher Settings

Closed side settings (CSS), stroke, and speed affect how aggressively the material is crushed. Tight settings often lead to faster wear, especially on the mantle and concave.

3. Feeding Practices

Improper or uneven feeding causes uneven wear patterns and may reduce the overall lifespan of wear parts. Consistent and centrally fed material helps maximize wear part usage.

4. Operating Conditions

Extreme temperatures, vibration levels, and load conditions can all influence how quickly wear parts degrade. Consistent monitoring and adjusting for these variables can extend wear life.

Signs That Cone Crusher Wear Parts Need Replacing

- Visible cracks or deformation on mantle or concave

- Excessive wear grooves or uneven wear patterns

- Decreased throughput or production capacity

- Increased vibration or noise levels during operation

- Larger than desired product size at discharge

Best Practices for Cone Crusher Wear Parts Maintenance

1. Regular Inspection

Frequently inspect all wear parts for signs of wear, cracking, or damage. Early detection prevents costly repairs or unplanned downtime.

2. Monitor Wear Life

Use wear monitoring tools and maintain wear logs. Predictive analytics can help schedule replacements before failures occur.

3. Rotate or Flip Liners

Some liners are reversible or designed to be rotated. Doing so can even out wear patterns and maximize their lifespan.

4. Maintain Proper Feed

Ensure even feed distribution and avoid feeding oversized or tramp material. Tramp metal should be removed using magnets or metal detectors.

5. Optimize Crusher Settings

Balance settings for product size and wear life. Avoid running the crusher at extremely tight settings for prolonged periods.

Benefits of Using High-Quality Cone Crusher Wear Parts

- Longer operating life and fewer replacements

- Lower maintenance and labor costs

- Improved crusher performance and consistent output

- Reduced downtime and operational delays

- Better particle shape and size control

- Enhanced energy efficiency

Aftermarket vs OEM Wear Parts

While OEM (Original Equipment Manufacturer) parts guarantee fit and compatibility, high-quality aftermarket parts from reputable suppliers can offer equal or superior performance, often at a lower cost.

Aftermarket options often include custom wear parts optimized for specific materials or operating conditions. These suppliers may also offer enhanced materials such as TIC inserts or ceramic composites that are not always available from OEMs.Visit our website https://www.chinastonecrushers.com/ for more details.

Technological Innovations in Wear Parts

Modern advancements have led to smarter, more durable wear parts:

- 3D Scanning & CAD Modeling: For precise fit and custom liner design

- Wear Sensors: For real-time monitoring and predictive maintenance

- Hybrid Liners: Combining multiple materials for extended wear life

- Improved Alloys: Tailored metallurgy based on application

Conclusion

Cone crusher wear parts are the unsung heroes of the crushing process. These components endure extreme stress and play a vital role in determining overall crusher performance. By choosing the right materials, following best maintenance practices, and utilizing modern innovations, operators can significantly extend wear life, reduce costs, and improve productivity.

Investing in high-quality cone crusher wear parts is not just about replacement — it’s about ensuring consistent, reliable, and efficient performance across your entire operation.